Product Usage

Our Kratom are offered exclusively as raw botanical materials for permitted technical or research applications. They are not food, animal feed, or in any way intended for human consumption. Please read our terms and conditions.

Important Notice

EUKratom does not promote or encourage the internal use of Kratom or any other botanical product sold on this site. All products must be used in accordance with their intended technical classification.

Cultivation, Harvesting and Drying Before Kratom Lab Tests

The journey begins in the country of origin, where kratom trees are cultivated under tropical conditions until the leaves reach the desired maturity. The leaves are hand-picked, cleaned from coarse dirt and spread out to dry – either in the sun or in controlled, ventilated drying rooms. The goal is to achieve a stable, low moisture level that reduces the risk of mold and makes the raw material suitable for storage. Only once drying is complete does the raw material move on to the first kratom lab tests, which form the foundation of the entire quality chain.

Internal Kratom Lab Tests in the Country of Origin and Milling

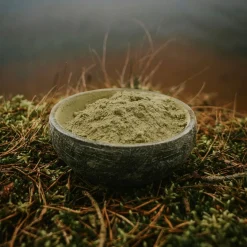

When the leaves are fully dried, representative samples from each batch are taken and sent for internal kratom lab tests. These tests analyze the microbiological status, such as the presence of bacteria, yeast and mold, as well as levels of heavy metals like lead, cadmium, arsenic and mercury. Only batches that meet the defined limits and internal quality standards are approved – the rest are rejected or handled according to deviation procedures. The approved dried leaves are then milled into a fine, homogeneous powder, sometimes sieved to achieve a consistent particle size, and filled into sealed inner bags which are packed in export-ready boxes.

Kratom Lab Results

Gamma Irradiation and Export After Kratom Lab Tests

The fully packed boxes are then sent to a licensed gamma irradiation facility, where they undergo a controlled irradiation process designed to further reduce microbial load and enhance product safety. After the process, documentation and certificates are issued, including details such as batch numbers, radiation dose and date, all of which are linked to each batch to ensure full traceability. The products are then palletized, accompanied by commercial invoices, packing lists and other export documents, cleared through customs in the country of origin, and shipped by sea or air freight to the Netherlands.

Final Quality Assurance: Kratom Lab Tests at Murray Brown Laboratories

Once the products arrive in the Netherlands, they go through import clearance and are transported to our warehouse. Here, an incoming goods inspection is carried out, where batches and documentation – including gamma irradiation records – are cross-checked. As a final safety step, samples from the delivered batches are sent for additional kratom lab tests at Murray Brown Laboratories. These independent analyses confirm the quality and safety of the product before it is finally released for sale and distribution, creating a clear, double-checked quality chain from leaf to finished product.

Deutsch

Deutsch Español

Español Čeština

Čeština